Water-borne microorganisms are ubiquitous and varied in their ability to survive and grow under different conditions. Therefore, an out-of-control water system can cause harm to the patient or adulterate pharmaceutical products. Purification of water is required to prevent interaction with drug substances or other ingredients in the product formulation. Water must also be microbiologically controlled and monitored.

While most well-designed water systems can be maintained in a state of control, microbiological problems can develop. Microbial adherence is a consequence of the balance of attractive and repulsive physicochemical interactions between bacteria the surface. The primary issue is biofilm formation—slime-like microbiological communities that occur when microorganisms adhere to a surface.

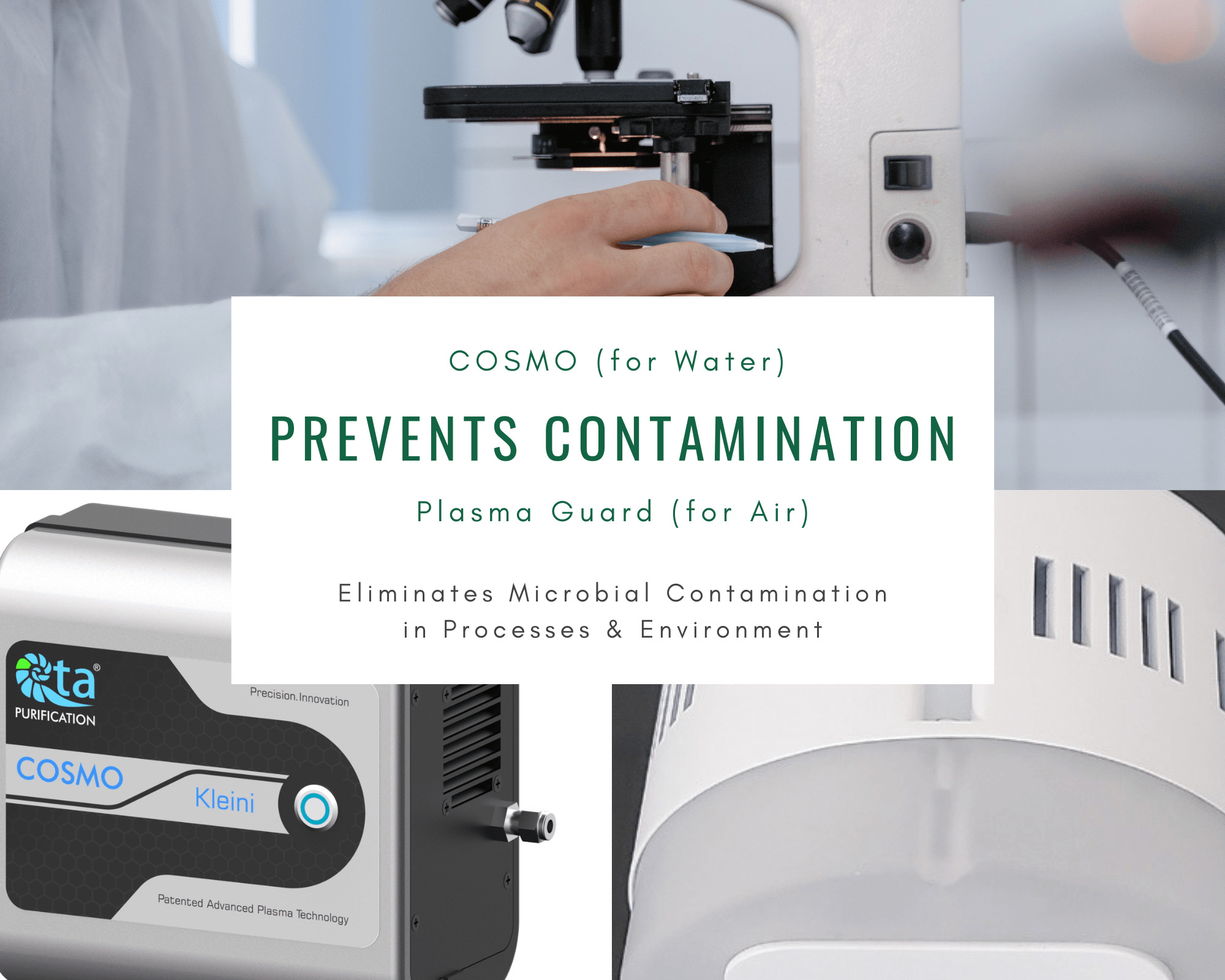

Eta Purification understands that pharmaceutical facilities are confronted with several challenges on a day-to-day basis with different phases of water generation, storage and distribution.

Advantages of using COSMO sterilization in the pharmaceutical process

- Rapidly destroys microorganisms by attacking their cell walls and

- Prevents bio-film formation on the inner walls of storage tanks, pipes & filters

- Eliminates any high temperature sterilization steps & saves energy

- Provides a broad-spectrum antimicrobial agent for the sterilization process

- Leaves no residues in the treated water & in the final product

- The antimicrobial agent is produced on-site and on-demand

- Suitable for use in all four-grades of pharmaceutical water